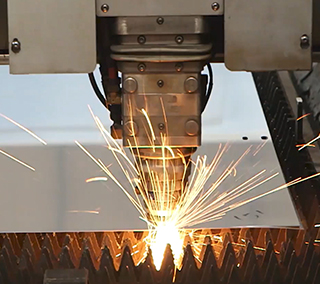

Chia Tai gurui electromechanical Co., Ltd., jointly invested and established by Chia Tai Group of Thailand and AGCO group of the United States, continuously innovates and innovates based on the product technology of AGCO's pig raising equipment AP, broiler breeding equipment Cumberland, egg chicken cage breeding equipment Tecno and storage equipment GSI, and customizes complete sets of high-end animal husbandry and breeding machinery for breeding enterprises all over the world, And provide overall solutions. The company's products cover breeding pigs, fattening pigs, laying hens and broiler breeding related equipment, mainly including feeding system equipment, environmental control system equipment, pig cage system equipment, laying hens breeding system equipment, breeding chickens flat breeding system equipment, etc. The company is located in Cixi National Modern Agricultural Industrial Park, covering an area of 200 mu. It was officially completed in August 2020 and fully mass produced. Zhengda gurui integrates six core processes: sheet metal, welding, roll forming, injection molding, extrusion and intelligent assembly. It is equipped with 47 sets of laser blanking production line, welding robot production line, injection molding and extrusion production line and roll forming production line. According to the product characteristics, it has developed 12 customized intelligent assembly lines to ensure the product processing and assembly accuracy. Using the latest SAP s / 4hana integrated intelligent ERP management system in Germany and Creo and Windchill Series graphics management software under PTC company in the United States, through the organic integration of digital management and flexible intelligent production line, Zhengda gurui has become the largest in the world, the most complete product categories and the most advanced processing equipment and technology, The product technology comes from the world's super first-class breeding equipment industrial base at the forefront. Advantages: cutting edge technology, precision machining, intelligent assembly, digital management, ultra-high cost performance